Variable Flow for Systems

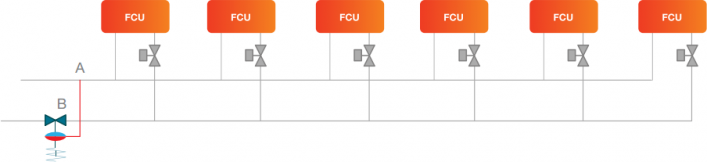

The water flowing around any cooling or heating water system is essentially lazy. It will always take the path of least resistance, leaving you with overflow closest to the pump and underflow furthest away from the pump.

Dynamic balancing valves force the water to flow evenly to all areas at design flow rate. In a constant volume system, a constant volume of water is pumped around a system utilising three or four port valves, and diverted back to the plantroom if not required.

Water is lazy and will take the shortest route!

- Nearest to the terminal = overflow

- Furthest to the terminal = underflow

Balancing forces design flow rates to all areas.

Variable Flow vs Constant Flow

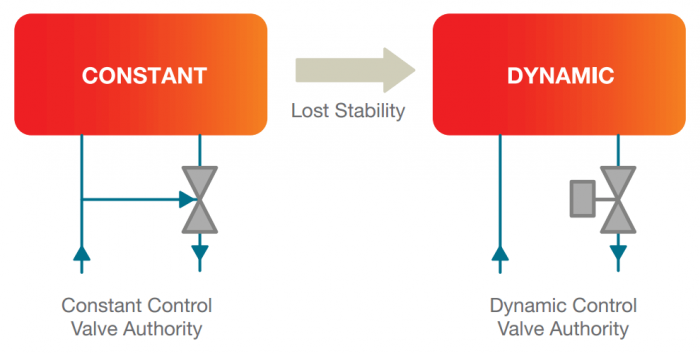

The Past: Constant Flow Systems

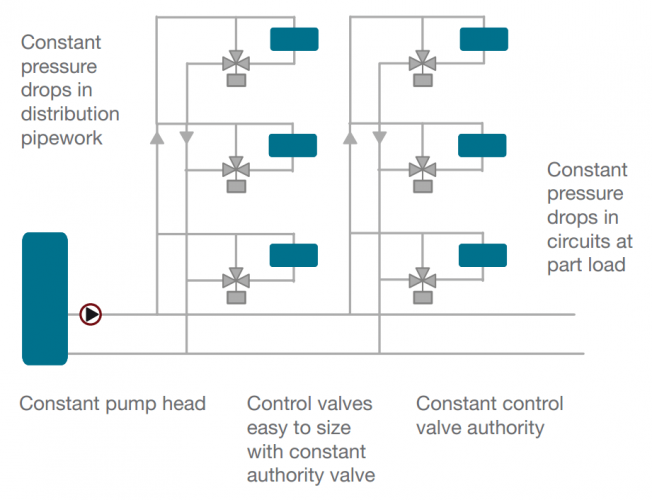

Until recently, constant flow systems were standard in heating, ventilation and air-conditioning (HVAC) systems. Constant flow uses a straightforward and simple design that can be applied to a broad range of projects. This involves the use of a fixed-speed pump that is set to the maximum load of the system. In addition, double-regulating balancing valves are manually set to regulate the impact of pressure changes across the system.

Although the capital costs of installing a constant flow system are relatively low, the manual balancing required is time consuming, complicated, laborious and system is inefficient. This results in higher running costs and subsequently resulting in higher CO2 emissions. Since most air-conditioning and water distribution systems only reach peak load for limited periods, energy is wasted by continually running the pumps at a fixed speed.

Inherently Very Stable

Why do we need Dynamic Balancing – Constant Volume?

Constant amount of water pumped around a system controlled by three or four port control valves and would be;

The Present & Future: Dynamic Balancing

Since 2000, there has been a marked rise in variable flow systems that use dynamic balancing in HVAC design. Why? Because they are significantly more energy efficient than constant flow systems.

This favoured method for heating and cooling systems uses inverter-driven pumps that operate at variable speeds to match the load. Double regulating, 2-Port motorised control valves are typically used to control flow to terminal fan coil units; in heating-only systems, a thermostatic radiator valve (TRV) is used to regulate flow to radiators.

In response to the global trend for variable flow systems, Hattersley offers a range of Differential Pressure Control Valves (DPCVs). Designed to be used in branches and/ or across air handling units, Hattersley DPCVs create stable areas (zones), protected from fluctuating system pressures, so that proportional balancing can be used.

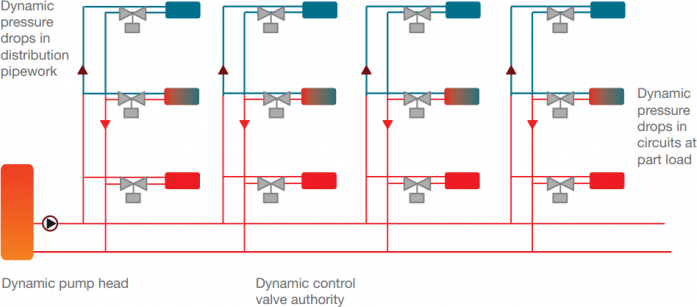

Inherently Very Unstable

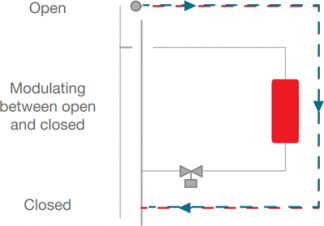

The DPCVs maintain constant differential pressure across a sub branch. This protects upstream or downstream control valves depending whether installed on the flow or return, from the effects of both high pressure and pressure variations, which can be caused by the movement of control valves in other branches.

In systems with 2-Port Control Valves which regulate volume, Hattersley DPCVs regulate differential pressure. Once a sub circuit has been commissioned, Hattersley DPCV protects the flow and balance from being affected by other sub circuits; this is referred to as a semi-automatic method of balancing the system.

Fully automatic balancing can be used in both variable and constant flow systems to enhance the performance of any HVAC system and save energy. As well as removing common problems caused by high and excessive system pressure – such as noisy valves – automatic balancing valves improves room temperature control.

Why do we need Dynamic Balancing – DPCVs for FCU?

To enable modulation 2-Port control valves to operate with an acceptable authority, a DPCV is installed to limit the circuit pressure differential. The installation of DPCVs on sub-branches with 2-Port control valves is therefore essential to achieve good control.

Inherently Very Unstable